Add to Cart

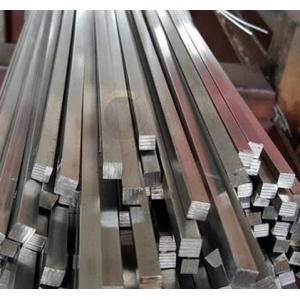

Stainless Steel Metal Square Rod Made of 904L Material Used in Acidic Environment

904L super austenitic stainless steel is a low-carbon, high-nickel, molybdenum austenitic stainless and acid-resistant steel. It is a proprietary material imported from France H·S. It has good activation-passivation transformation ability, excellent corrosion resistance, good corrosion resistance in non-oxidizing acids such as sulfuric acid, acetic acid, formic acid, and phosphoric acid, and good corrosion resistance in neutral chloride-containing media It has good pitting resistance and good resistance to crevice corrosion and stress corrosion.

1. Material:

Carbon Steel:Q235,Q195,Q345,etc

200 series:201 202

300 series :301 304 304L 309S 310S 316L 317L 321 904L

400 series :409L 410 420 430 439 441

2. Size:

Length:1-12m

Edge Width: 10-800mm or as customer required

We have a professional processing factory to cut stainless steel sheets.

3. Surface:

2B BA NO.4 Mirror 8K pvc coated.

Surface Classification and Processing:

N0.1-After hot rolling, it is heat treated and pickled.

2B-After cold rolling, heat treatment, pickling or similar treatment is carried out, and finally it is smoothed to obtain proper gloss.

2D-After cold rolling, heat treatment, pickling or similar treatment or matt surface.

3# 100~200# The product is ground with grinding belt.

4# 150~180# The product is ground with grinding belt.

HL Grinding material with appropriate grain size is polished to make the surface continuously abrasive.

You could also ask for other special treatment.We have a stainless steel processing factory in Wuxi.

4. Standard:

GB JIS ASTM EN DIN AISI

5. Packing:

Standard stainless steel shipping packaging or as customer required.

6.Processing technology of stainless steel square steel:

a) Drawing deep processing: it is easy to generate frictional heat, so use stainless steel with high pressure resistance and heat resistance, and remove the oil attached to the surface after the completion of the molding process.

b) Welding: Before welding, the rust, oil, water, paint, etc. that are harmful to welding should be completely removed, and the welding rod suitable for the steel type should be selected. The spot welding time interval is shorter than that of carbon steel spot welding. Stainless steel brush should be used to remove welding slag. After welding, in order to prevent local corrosion or strength reduction, the surface should be polished or cleaned.

c) Cutting and stamping: Since stainless steel has higher strength than general materials, higher pressure is required for stamping and cutting. When the gap between the knife and the knife is accurate, poor shearing and work hardening will not occur. Plasma or laser cutting is best When gas cutting or arc cutting has to be used, the heat-affected zone is ground and heat treatment is necessary.